Our Services

Building successful products requires more than good ideas—it demands engineering expertise at every stage. Partner with HUB for the technical knowledge and practical solutions that turn concepts into competitive products.

Design & prototyping

We transform your concepts into tangible, testable prototypes that validate functionality and design intent. Our iterative approach ensures each prototype brings you closer to a manufacturable solution. From initial sketches to functional models, we make your ideas real.

systems engineering

We guide products through the complete development lifecycle, from concept refinement to production-ready specifications. Our systematic approach addresses technical challenges, manufacturability constraints, and performance requirements. We ensure your product is optimized for both function and efficient production.

process and automation

We design and implement manufacturing processes, tooling, and automation systems that optimize production efficiency. Our expertise spans fixture design, process optimization, and automated solutions tailored to your production volumes. We turn manufacturing challenges into competitive advantages.

design & Prototyping

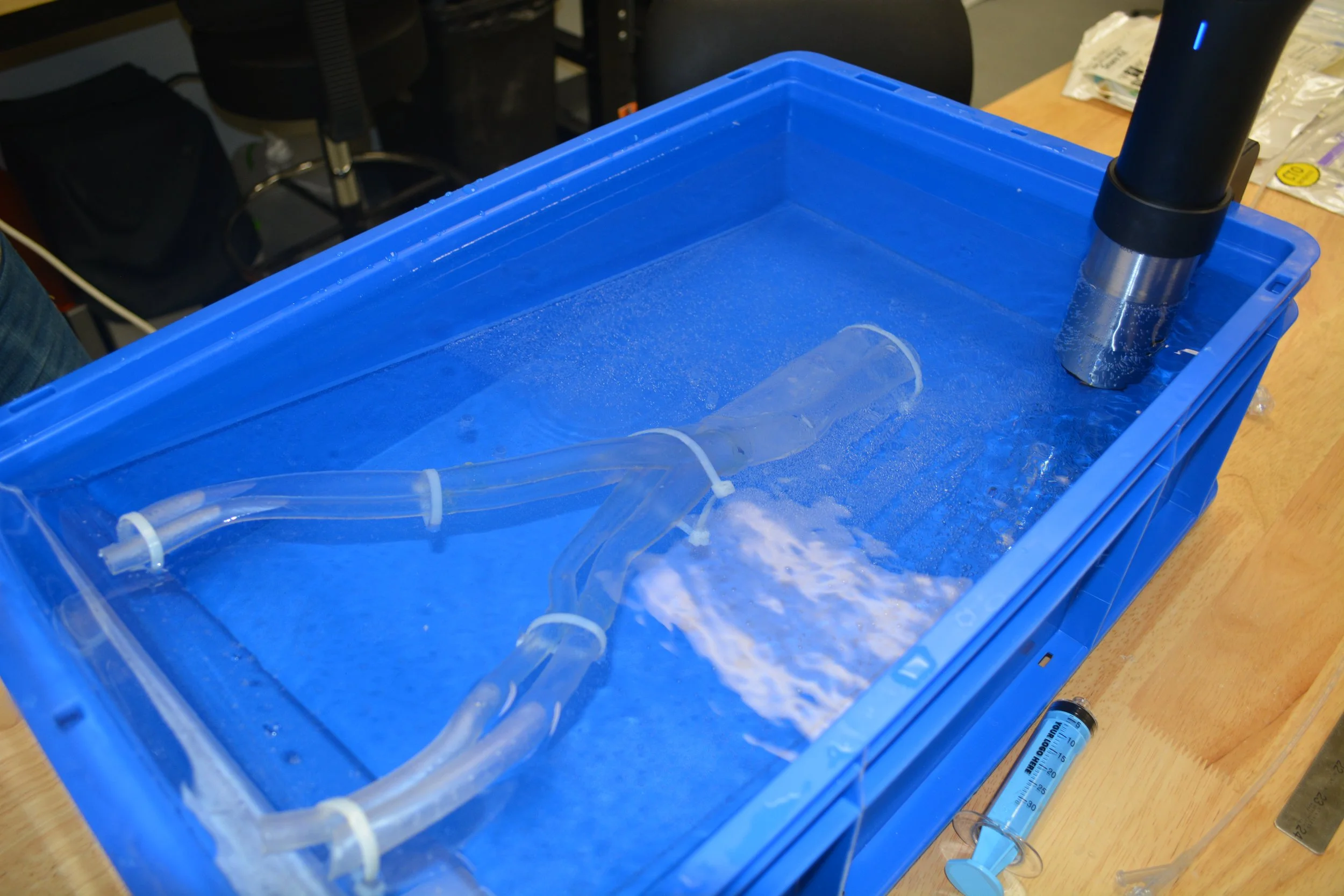

We transform your medical device concepts into tangible, testable prototypes that validate functionality and design intent. Our iterative approach ensures each prototype brings you closer to a manufacturable solution that meets strict medical industry standards.

From interventional catheters and integrated devices to surgical instruments, we understand the unique challenges of medical device development. Our prototyping process addresses critical factors like biocompatibility, sterilization requirements, and regulatory considerations from day one. Whether you're developing a minimally invasive surgical tool or a complex integrated diagnostic device, we make your ideas real and ready for the next development phase.

Systems engineering

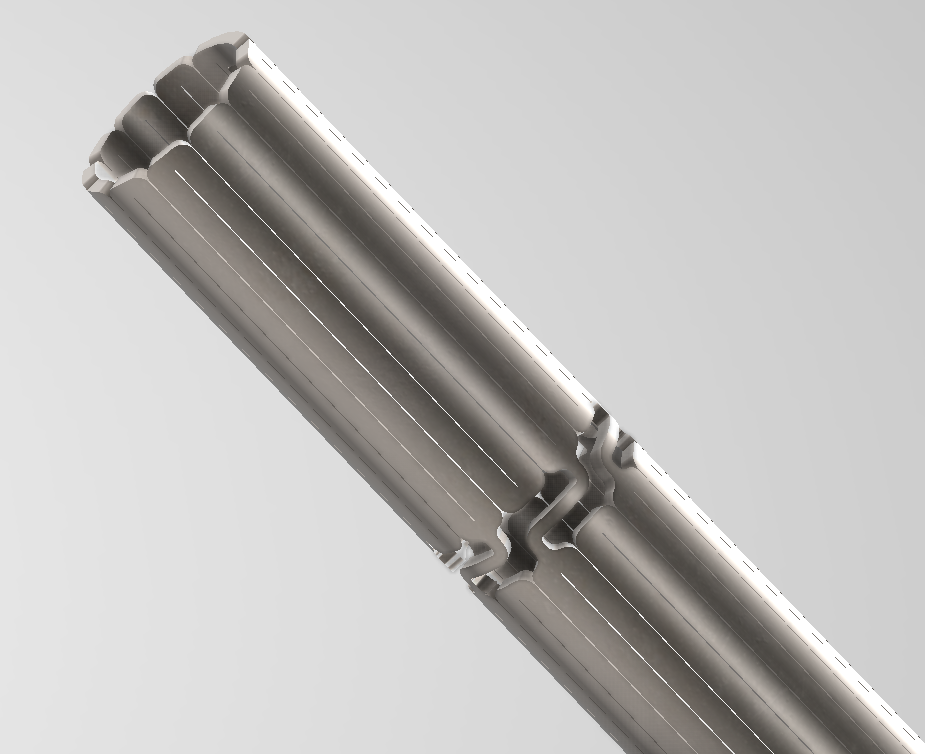

We guide medical devices through the complete development lifecycle, from concept refinement to production-ready specifications. Our systematic approach addresses technical challenges, manufacturability constraints, FDA requirements, and ISO 13485 quality management standards specific to medtech and biotech applications.

Our expertise spans interventional catheters that require precise navigation and flexibility, integrated devices that combine multiple functions seamlessly, and surgical instruments that demand reliability under critical conditions. We ensure your product is optimized for both clinical effectiveness and efficient manufacturing, while maintaining compliance with ISO 13485 and medical device regulations throughout the development process.

Process & Automation

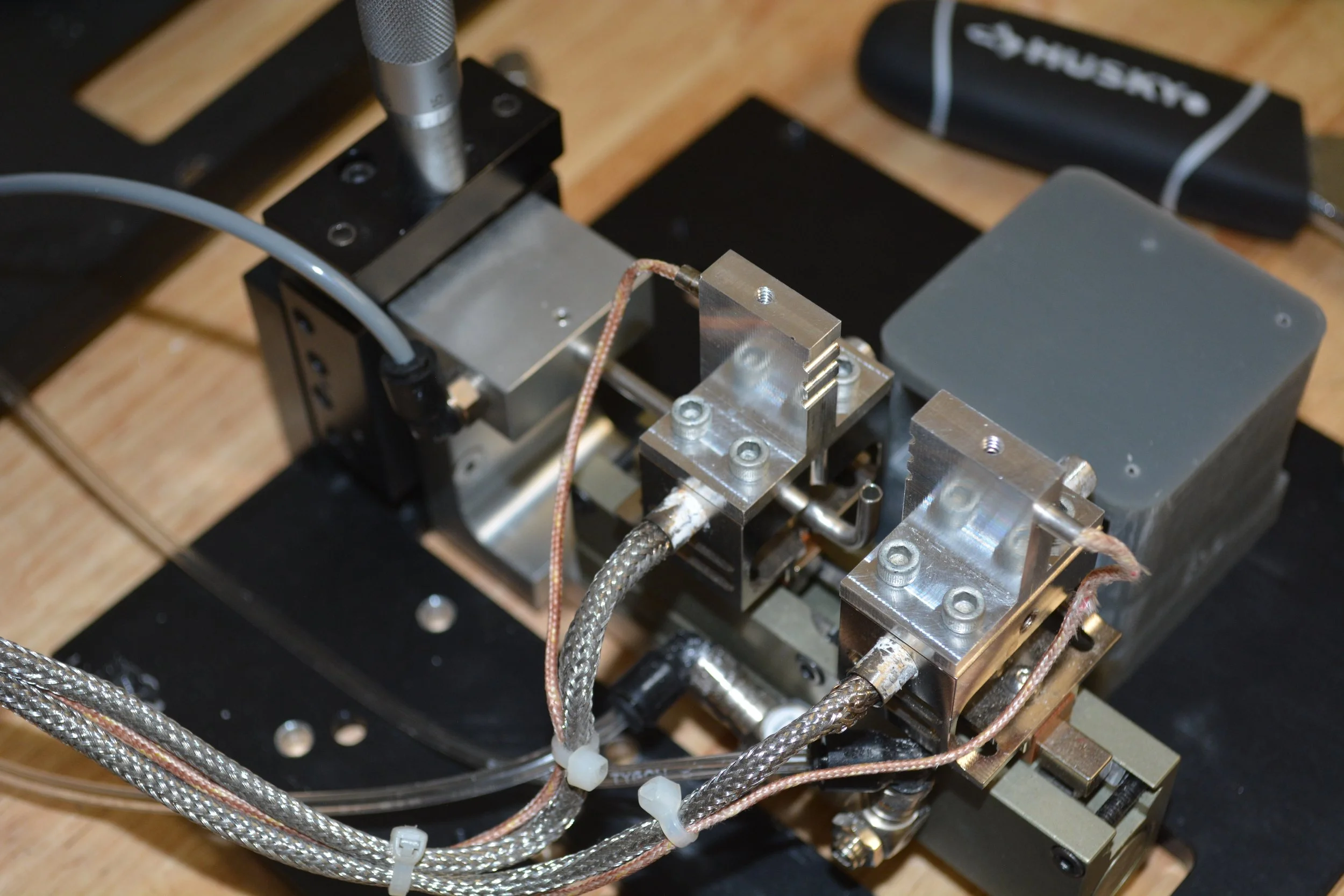

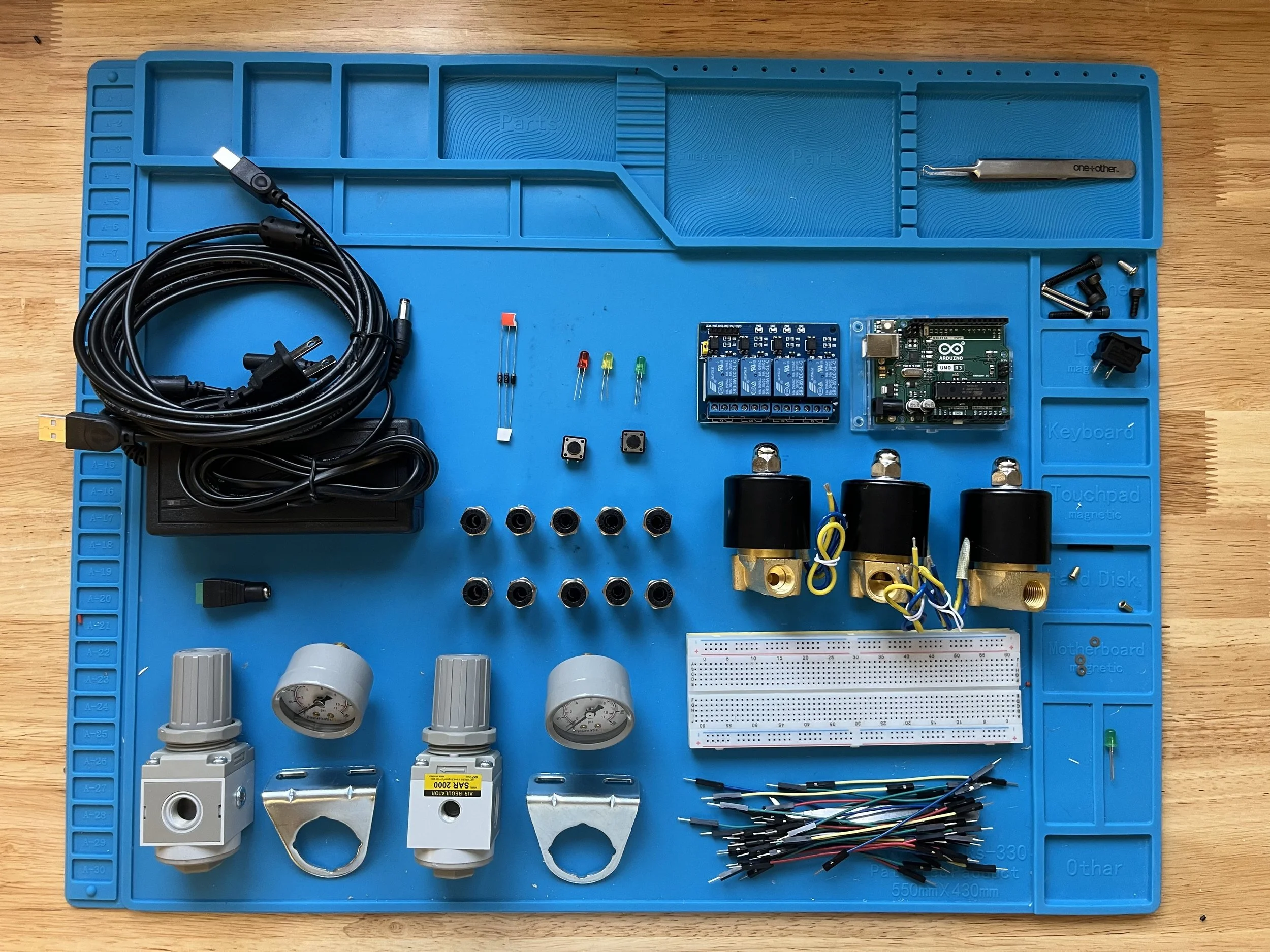

We design and implement manufacturing processes, tooling, fixturing, and automation systems specifically tailored for the precision demands of medical device production. Our expertise spans both medtech and biotech sectors, where quality and consistency aren't just goals—they're regulatory requirements.

From specialized tooling for catheter manufacturing to automated assembly systems for surgical instruments, we create production solutions that ensure repeatability and traceability. Our process engineering includes cleanroom-compatible equipment design, validation protocols, and automation systems that meet the stringent quality standards required for medical device manufacturing. We turn complex manufacturing challenges into competitive advantages while maintaining the highest standards of medical device production.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!